PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

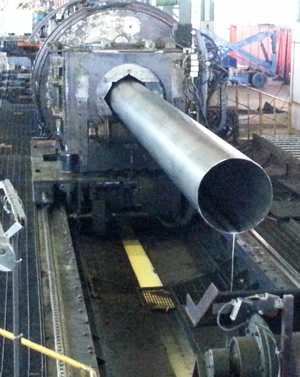

ERW/HFW Pipe

Application:Used for Oil/Gas/Water transmission,Machinery Manufacturing

Size:OD: 21.3-660mm,WT: 1.0-20mm,LENGTH: 5.8/6/11.8/12m

Pipe Standard: API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70

ASTM A53/A252/A500/A178/A135

EN10210/EN10219/EN10217/EN10208/EN10297

JIS G3441/G3444/G3445/G3452/G3454/G3456

BS1387/AS1163

hiddenValue

PRODUCT DETAILS

Description

The ERW steel pipe is also known as straight joint pipe. According to the wall density, the bonded tube is categorized into typical types and thick-walled types. We can offer items with personalized wall thickness according to customers’ particular requirement with a thickness deviation of no more than 0.25 mm.With sizes between 1/2 inch and 24 inch, our ERW steel pipes go through rigorous examinations and tests, so about make sure the welding quality, external size precision, ovality, cut lengths, pipe end quality, wall density tolerance, and packaging quality are all conforming to API5L, ASTMA53, GB/T9711.1, or GB/T3091 standards. Also, we can make the item according to the standard needed by customers.

Standard

for erw pipe

ASTM A53 B, ASTM A178, ASTM A252 GR.2

API 5L X42/46/52/56/60/70

ASTM A500, ASTM A513

EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H

for efw pipe

carbon steel efw pipe: ASTM A671,ASTM A672

alloy steel efw pipe: ASTM A691

Sizes

Out diameter

1/2" -24" (21.3mm-610mm)

Wall Thickness

1.65mm-20mm

|

|

|

|

|

|

UNCOILING & FLATTENING Incoming coils are peeled and unwrapped for presentation into the flattener rolls. Flattening removes the coil set to produce a flat steel strip. |

COIL JOINING Coil ends are joined together with a butt weld to produce a continuous strip. |

EDGE TRIMMING Slitter blades and edge milling trims strip edges to provide the precise strip width required during the forming and ERW seam welding process. |

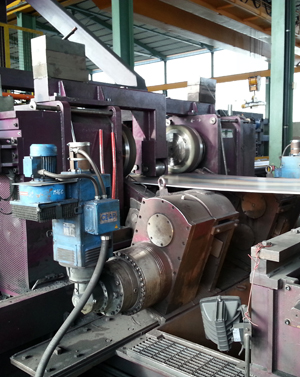

FORMING The forming process begins at the Breakdown Pass where the material is gradually bent from a flat steel strip into a rounded tube for presentation to the ERW seam welder. |

|

|

|

|

|

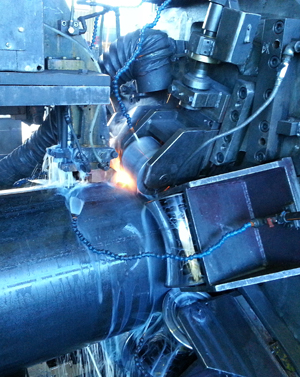

WELDING A high frequency electrical current flows through contact tips into the strip edges to produce the heat required for bonding the strip edges together as the material passes through the weld roll stand. |

QUALITY CONTROL Once the welding is complete, the finished pipe is visually inspected by Quality Control (QC) and, if required, Ultrasonic (UT) testing is performed to ensure the weld is defect-free. |

PIPE SIZING/STRAIGHTENING The Sizing Section squeezes the welded pipe into the precise roundness, outer diameter, and straightness tolerances specified by the customer. |

PIPE CUTTING The flying cut-off saw attaches to the pipe as it is being produced and cuts the pipe to the length specified by the customer. |

Specification&Standard

Small diameter

|

Out diameter |

Sch 5 |

Sch 10 |

Sch 40 |

||||

|

Inch |

mm |

Thickness |

Kg/mtr |

Thickness |

Kg/mtr |

Thickness |

Kg/mtr |

|

1/2" |

21.3 |

1.65 |

0.81 |

2.11 |

1.01 |

2.77 |

1.29 |

|

3/4" |

26.7 |

1.65 |

1.03 |

2.11 |

1.30 |

2.87 |

1.71 |

|

1" |

33.4 |

1.65 |

1.31 |

2.77 |

2.12 |

3.38 |

2.54 |

|

1 1/4" |

42.2 |

1.65 |

1.93 |

2.77 |

3.15 |

3.68 |

4.11 |

|

1 1/2" |

48.3 |

1.65 |

1.93 |

2.77 |

3.15 |

3.68 |

4.11 |

|

2" |

60.3 |

1.65 |

2.42 |

2.77 |

3.98 |

4.81 |

5.31 |

|

3" |

88.9 |

2.11 |

4.58 |

3.05 |

6.54 |

5.49 |

11.45 |

|

3 1/2" |

101.6 |

2.11 |

5.25 |

3.05 |

7.52 |

5.74 |

13.77 |

|

4" |

114.3 |

2.11 |

5.25 |

3.05 |

7.52 |

5.74 |

13.77 |

|

5" |

141.3 |

2.77 |

9.50 |

3.40 |

11.74 |

6.55 |

22.10 |

|

6" |

168.3 |

2.77 |

11.47 |

3.40 |

14.04 |

7.11 |

28.68 |

|

8" |

219.1 |

2.77 |

14.99 |

3.76 |

20.25 |

8.18 |

43.16 |

Large diameter

|

OD |

WT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inch |

mm |

8 5/8" |

219.1mm |

10 3/4" |

273.1 |

12 3/4" |

325.0 |

14" |

355.6 |

16" |

406.4 |

18" |

457.7 |

20" |

508.0 |

24" |

610 |

24 4/5" |

630.0 |

|

0.157 |

4.0 |

---- |

--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.197 |

5.0 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

|

|

|

|

|

|

|

|

|

|

0.236 |

6.0 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

|

|

|

|

|

|

0.276 |

7.0 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

|

|

|

|

0.315 |

8.0 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

|

|

0.354 |

9.0 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

|

|

0.394 |

10.0 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

0.133 |

11.0 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

0.492 |

12.5 |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

0.551 |

14.0 |

|

|

|

|

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

0.630 |

16.0 |

|

|

|

|

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

0.689 |

17.5 |

|

|

|

|

|

|

|

|

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

0.748 |

19.0 |

|

|

|

|

|

|

|

|

|

|

--- |

--- |

--- |

--- |

--- |

--- |

--- |

--- |

|

0.787 |

20.0 |

|

|

|

|

|

|

|

|

|

|

|

|

--- |

--- |

--- |

--- |

--- |

--- |

ASTM 5L, ASTM A53, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672, EN 10217

Steel Grade:

API 5L: PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

ASTM A53: GR.A, GR.B,ASTM A500 JIS G3466

EN: S275, S275JR, S355JRH, S355J2H,EN10219-1 ,EN10217-1

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360-L555

|

ASTM A53 |

Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

API 5L |

Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) |

|

A252 |

Standard Specification for Welded and Seamless Steel Pipe Piles |

|

A500 |

Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

|

A135 |

Standard Specification for Electric-Resistance-Welded Steel Pipe |

|

A178 |

Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes |

|

ASTM A249 |

Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser tubes |

|

ASTM A250 |

Specification for Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater tubes |

|

ASTM A688 |

Specification for Welded Austenitic Stainless Steel Feedwater Heater tubes |

|

ASTM A778 |

Specification for Welded, Unanneled Austenitic Stainless Steel Tubular Products |

|

ASTM A803 |

Specification for Welded Ferritic Stainless Steel Feedwater Heater tubes |

|

ASTM A501 |

Specification for Hot-Formed Welded and Seamless Carbon Steel Structural tubing |

|

ASTM A847 |

Specification for Cold-Formed Welded and Seamless High Strength, Low Alloy Structural Tubing with Improved Atmospheric Corrosion Resistance |

|

ASTM A618 |

Specification for Hot-Formed Welded and Seamless High-Strength Low-Alloy Structural tubing |

|

ASTM A214 |

Specification for Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser tubes |

|

ASTM A249 |

Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser tubes |

|

ASTM A498 |

Specification for Seamless and Welded Carbon, Ferritic, and Austenitic Alloy-Steel Heat-Exchanger tubes with Integral Fins |

|

ASTM A851 |

Specification for High-Frequency Induction Welded, Unannealed, Austenitic Steel Condenser tubes |

|

ASTM A554 |

Specification for Welded Stainless Steel Mechanical tubing |

|

ASTM A513 |

Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical tubing |

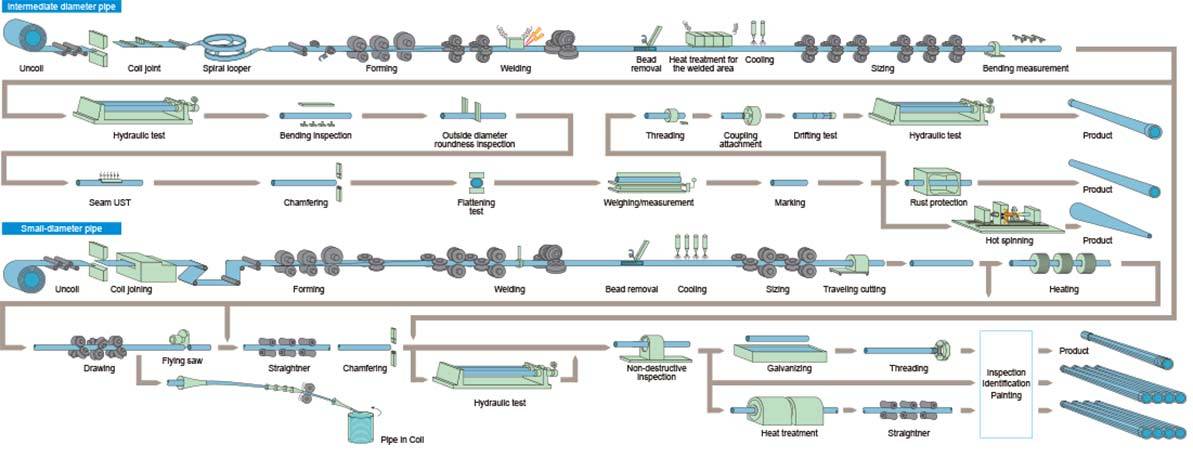

Process

Manufacturing Process of ERW steel pipe

Electric Resistance Welded (ERW) pipe is manufactured by cold forming a flat steel strip into a rounded tube and passing it through a series of forming rollers to obtain a longitudinal seam. The two edges are then simultaneously heated with a high frequency current and squeezed together to form a bond. The longitudinal ERW seam does not require filler metal.

Packing

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleeve, and sackcloth with several steel strips, Plastic caps.

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, RT TEST, UT TEST)

Storage video

Warehouse storage

The group company and factory cover an area of more than 800 mu, with more than 1,500 employees, and its business covers more than 20 countries and regions around the world. Xinghan Group is committed to developing new types of steel products and building a first-class coated sheet and steel manufacturing enterprise with international competitiveness. Xinghan Group hopes to grow into a widely respected and sustainable global resource-based enterprise through continuous pursuit of excellence, create better social, economic and environmental benefits, and bring more competitive value returns to employees and customers.

Packing and delivery

The company has major production lines such as pickling, cold rolling, hot dip galvanizing, hot dip galvanizing, thick plate galvanizing and color coating, forming an annual production capacity of 1 million tons of pickling coil, 1 million tons of cold rolled sheet and 900,000 tons of hot dip galvanized sheet. Galvanized and hot-dip galvanized aluminum zinc silicon steel sheet scale 450,000 tons thick galvanized steel plate scale 300,000 tons color coated steel plate scale is one of the largest steel and non-ferrous metal smelting and processing suppliers in Shandong Province.

Customer visit

The company adheres to the development strategy of "seeking development by science and technology, seeking efficiency by management", adheres to the core values of "people-oriented, integrity, responsibility and excellence", adheres to the development system of "green products and green industry", "promotes high-quality beyond development in an all-round way", and realizes the vision of "building a first-class aluminum processing service enterprise with international competitiveness".

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

RELATED PRODUCTS

GET A FREE QUOTE